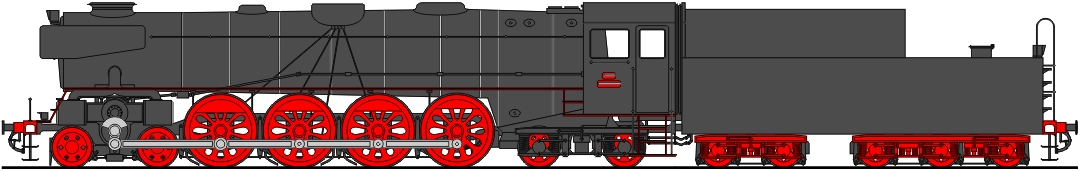

Class 465A

6-Cylinder Triple-Expansion Compound

Motor

Express Passenger Locomotive

Designed by

Artur Gorote

Built in 2006 at RSR

Works, Bevice-Akohniçe, Ruhnia

Class 465A

6-Cylinder Triple-Expansion Compound

Motor

Express Passenger Locomotive

Designed by

Artur Gorote

Built in 2006 at RSR

Works, Bevice-Akohniçe, Ruhnia

The constant search for improved balancing in the reciprocating steam locomotive has led over the decades to many different cylinder arrangements. One solution that was often proposed by the locomotive builders but almost never adopted by their customers was the high-speed reciprocating steam motor powering the driving wheels through gearing, jackshaft and siderods, an arrangement normally associated with turbines and early electric locomotives. The five-cylinder compound drive that was applied by Jochann Ketterik from the early 1980s onwards came in for much criticism in engineering circles because of the still large reciprocating masses, although in practice these were not the problem they were predicted to be. The salient features of the class 665A and 655C goods engines, whose construction was still being debated, did not lend themselves well to adaptation for passenger work, owing to the need for the Withuhn inside coupling rods to have an axle to themselves, as it were. So it was that Gorote decided to dust off the steam motor principle to see whether it would be of use to the RSR. Certainly, the problems of balancing, hunting and dynamic augment are absent, since only rotating masses need to be balanced in the running gear. Additional advantages of the steam motor are optimum lubrication, owing to the fully-enclosed crankcase, lighter (because much smaller) pistons and connecting rods, allowing considerably higher piston speeds, simpler (and thus cheaper) maintenance due to a lack of inside motion and a more even draw on the fire from the lighter and more rapid exhaust rhythm.

The 465A's steam motor has two high-pressure cylinders, two medium- and two low-pressure cylinders. All cylinders are double-acting in the conventional manner. Poppet valves are driven by gear trains mounted inside the crankcase. No problems have been encountered with motor reliability. Tailoring the reduction gear ratio for the main drive permits an optimum relationship between required operating speed and tractive effort on the one hand and driving wheel diameter on the other so that, in theory, all locomotives could be basically identical. The potential of this realisation is still being studied, albeit with low priority.

The prototype

locomotive, no. 465A.001, was first steamed in September 2006 and

hauled test trains over the main lines of the RSR and RK. These trials

continued and remained in progress and under evaluation for many years. Initial results looked promising, the most serious

problem being the weak draught at low speeds unless

the engine is working very hard; under such conditions the blower is

usually needed at less than 50 km/h. As was expected, the riding of the

engine is extremely smooth and completely free of hammerblow. The highest speed achieved so far, once the engine was run

in, was 163 km/h with a load of 560 tonnes on the almost level

riverside line between Belšinohra and Martihpe.

Text and graphics © Norman Clubb 2012